AI-OPTIMIZED DESIGN OF EXPERIMENTS

The new era of digital bioprocessing

A new approach for new technologies

Traditional DoE and factorial designs have long provided a structured, rigorous framework for bioprocess development, built around the analytical capabilities of multiple linear regression (MLR). As bioprocesses grow more complex, our standard approach is being stretched to its limits. Scientists are increasingly forced to trade off between budget and time constraints on the one hand, and the desire to deepen process understanding through additional experimentation on the other. Hybrid modeling technology is offering new capabilities and possibilities to process development.

Hybrid models increase insight with fewer experiments

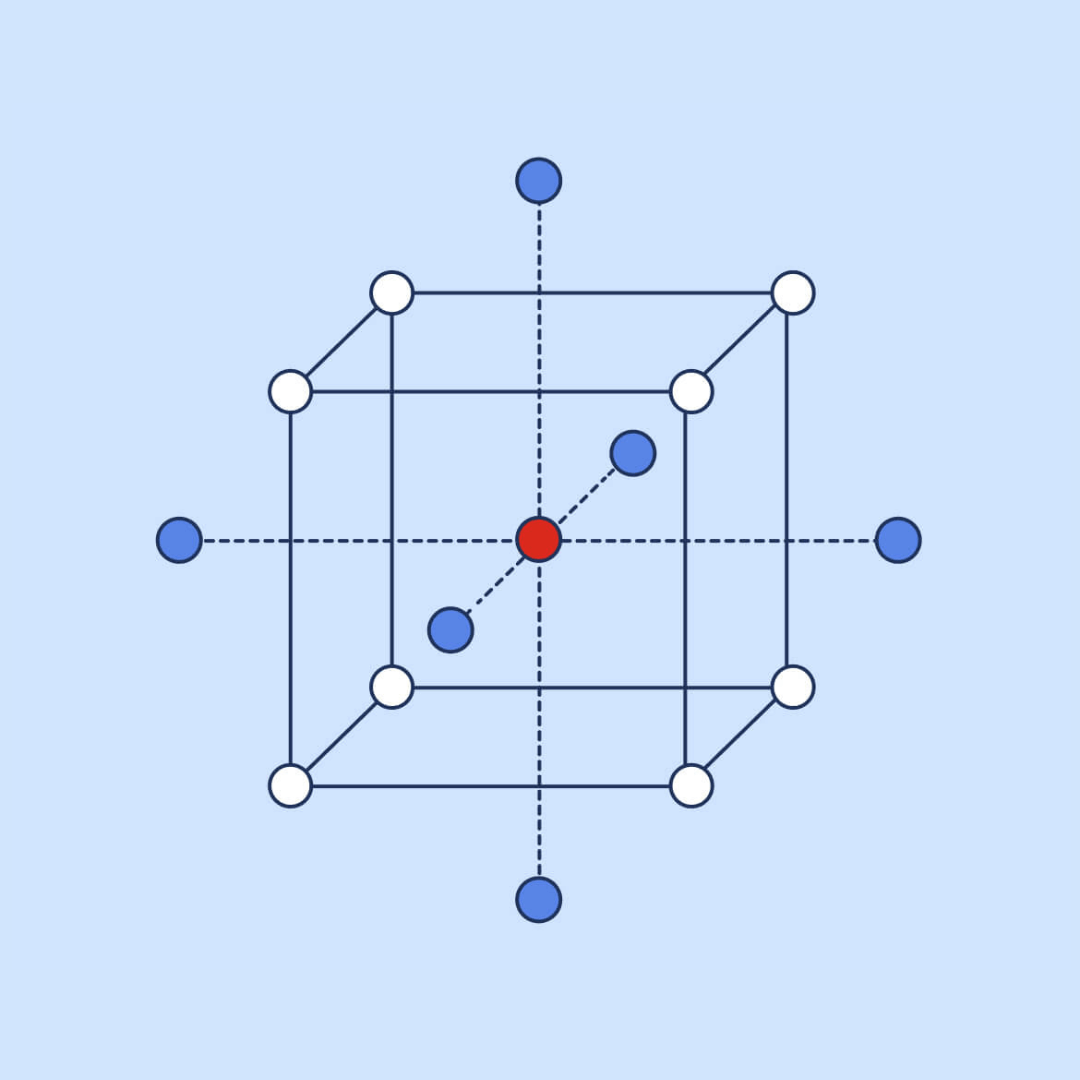

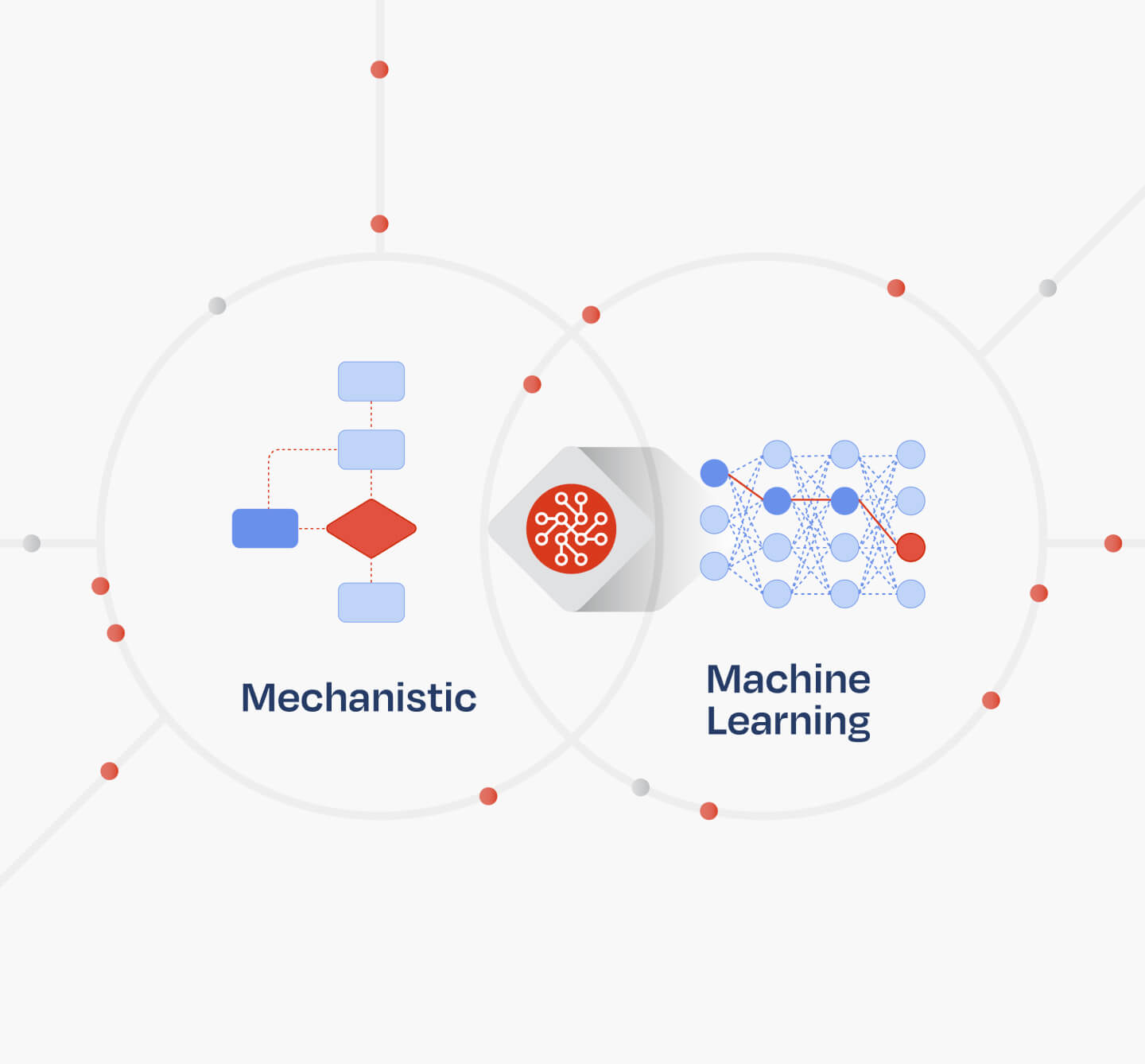

With a mechanistic backbone encoding known process behavior, hybrid models require fewer experiments to understand the design space, yet still offer interpretability and the power to extrapolate. Machine learning then takes a data-driven approach to learn the specific dynamics of the process. The result: faster, more impactful insight from fewer experiments.

Reduce time to insight with iterative development loops

Development teams invest considerable time and resources in disconnected experimental campaigns, with often inconsistent results. DataHow’s development framework and iterative development loops accelerate the time to insight by favouring shorter experimental sprints where scientists learn, iterate, and refine. Each loop generates actionable knowledge that guides the next step, ensuring exploration of the design space is purposeful and aligned with clear objectives.

Begin with available knowledge

Process development traditionally starts each project from scratch, relying on large experimental campaigns to generate insight. DataHow’s methodology reduces this burden by reusing and transferring knowledge from historical data, while focusing on new experiments where knowledge gaps exist.

Digital Development Assets & Digital Twins

Processes developed under this approach produce a set of valuable digital assets that can be leveraged throughout the process lifecycle. Experimental data feed into process models, which generate insights that support the optimization of process recipes. With each development loop, these assets are refined and strengthened, culminating in a complete body of digital process knowledge that is seamlessly transferred to manufacturing.

Crucially, the models serve as the engine of a digital twin, where all learned insights, knowledge and learning from development are leveraged to monitor and control manufacturing processes in real-time.

Ready to start your digital transformation?

Meet with one of our bioprocess development experts for a demo of DataHowLab and see how holistic digital modeling, data analysis, and data management can transform your operation.